Air-source heat pumps have an exterior compressor unit. In the Winter, the heat pump’s reversing valve causes the exterior coils to become cold. The 2nd. law of thermodynamics tells us, simply put, that “heat moves towards cold.” The latent heat in the outside air moves into the coil’s refrigerant, is made hotter through compression, and is presented to the home’s return air stream in the interior cabinet.

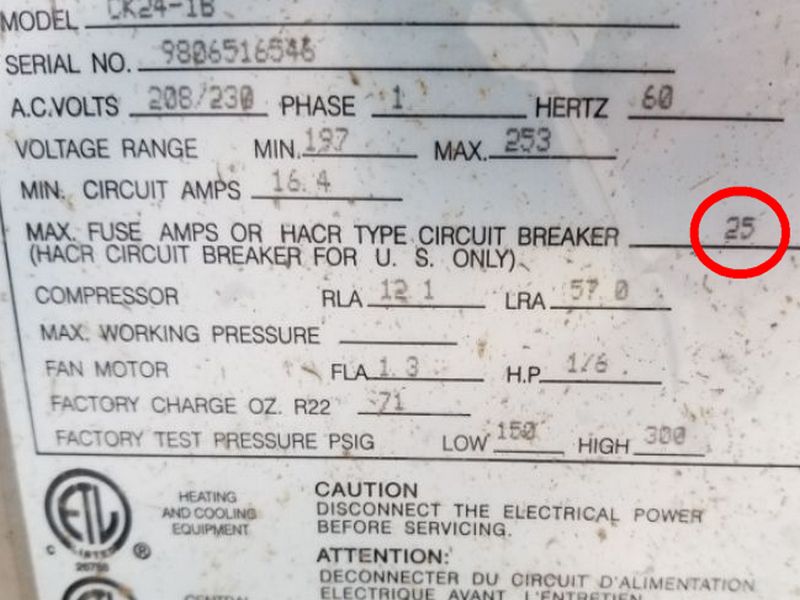

Evaluating a heat pump exterior unit (compressor) is much the same as for a central AC system. The cabinet should be level (a slight tilt for drainage is fine), on a secure pad above grade, and clear of foliage. Inspect for damage and dirt buildup. Dryer vents shouldn’t discharge on the compressor. Look for oily stains on the lineset, which indicates a possible refrigerant leak. The larger “suction” line should be insulated. Confirm that the exterior capacity is not larger that the interior coil capacity. The compressor has a maximum OCPD rating; the breakers or fuses cannot exceed this. The unit should run smoothly and quietly, and be free of ice. A very light frost is OK, but should clear quickly during the defrost cycle, signaled by a “whooshing” sound. An electrical disconnect must be within sight when standing at the compressor.

Reversing Valve:

The insulation is damaged or missing at the compressor’s suction line. This affects the system’s efficiency. Install an exterior-grade pipe insulation on the suction line.

There is an excess of bushes, shrubs, and debris around the exterior compressor. This restricts airflow, and affects the efficiency as well as the life expectancy of the unit. Remove the foliage and debris.

The compressor is not level. This will damage the compressor motor. Hire an HVAC contractor to make required repairs.

The compressor does not have a support pad and is resting directly on the ground. This is not a stable base, and settlement can damage the system. Hire an HVAC contractor to install the compressor on a support pad.

The compressor unit at the exterior is in contact with the soil and/or mulch. Moisture and lawn and garden chemicals can corrode the cabinet and cause a premature failure. Remove the soil and mulch.

The compressor coils are dirty. This can affect efficiency. Hire an HVAC contractor to clean the coils.

The compressor has damaged fins. This causes reduced performance and system failure. Hire an HVAC contractor to evaluate the compressor and to make required repairs.

The compressor has ice on the refrigerant line and coils. This implies a low refrigerant charge or inadequate air flow. This will affect proper performance and can damage the system. Hire an HVAC contractor to evaluate the system and to make required repairs.

The circuit breaker or fuse for the compressor is larger than the maximum allowed as noted on the compressor’s rating plate. This can damage the compressor, and may void the system warranty. Hire an electrician to replace the breaker or fuse.

The compressor disconnect is missing or improperly located. This is a safety issue. The disconnect must be “within sight of the compressor,” or a lock-out device should be installed at the breaker panel. Hire an electrician to install a disconnect.

The compressor is installed in a restricted space that may prevent proper access by service personnel. This can hinder appropriate maintenance and cause additional expenses. Hire a contractor for an evaluation and to make repairs as needed.