All combustion heating appliances produce toxic exhaust. Carrying that exhaust entirely away from the furnace or boiler and to the exterior of the home is fundamental to a safe installation. As homes become “tighter” there is even less margin of error in ensuring an acceptable indoor environment. As covered in other sections, chimneys and ventilation devices can affect safety. High-efficiency condensing appliances require specific vents that adhere to specific standards. Some obsolete and recalled vents are still in use. Overall condition, correct installation and termination, and signs of problems must be evaluated closely.

Ensure that you are familiar with Category III and IV appliance venting requirements. Always inspect for odors, acidic precipitation, and other signs of back-drafting. Report any damage, corrosion, vent openings, inadequate flue support, negative slope, and terminations too close to the ground, windows, or adjacent structures. Draft control devices such as barometric dampers and spill switches should be assessed. Safe clearances to combustibles must be maintained.

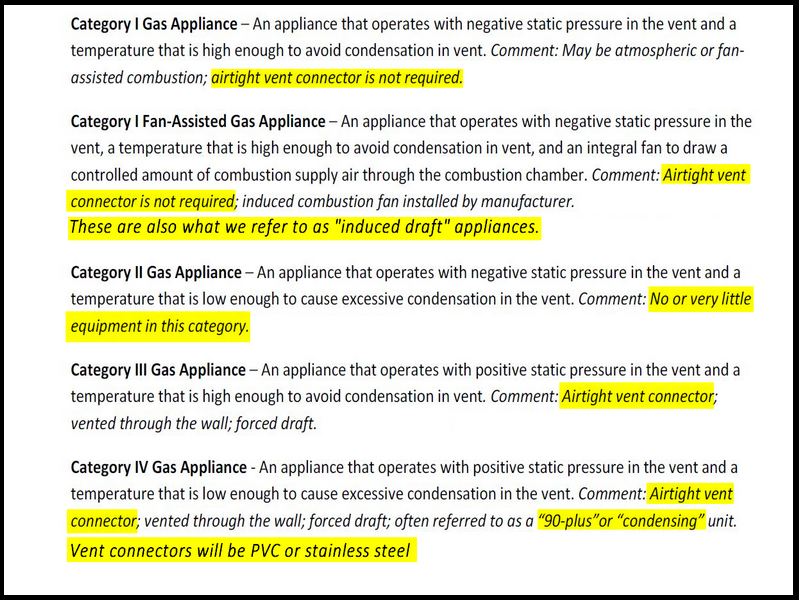

Appliance Categories and Venting:

Category III – IV Stainless Steel Vent Pipe:

The exhaust pipe is too close to combustible materials. This is a safety hazard. Hire an HVAC contractor to make the required repairs.

The exhaust pipe is improperly sloped. They must run uphill at least 1/4″ per foot to prevent exhaust gases from entering the living spaces. Hire an HVAC contractor to make the required repairs.

The exhaust pipe is not adequately supported. This can allow damage and is a safety concern. Hire an HVAC contractor to make the required repairs.

The exhaust pipe is inadequately sealed or has gaps. Openings in the flue permits exhaust gases to enter the living spaces. Hire an HVAC contractor to make the required repairs.

The exhaust pipe is corroded. This is a hazardous condition that permits dangerous flue gases to enter the living area. Hire an HVAC contractor to make the required repairs.

The exhaust vent is improperly-installed. It is routed through the HVAC return duct. This is a significant risk for allowing toxic flue gases into the house air. Hire an HVAC contractor to make the required repairs.

The exhaust vent is leaking. Condensate is visible. This can permit flue gases to enter the living area. Hire an HVAC contractor to make the required repairs.

The exhaust vent is leaking. Condensate is visible. This can permit flue gases to enter the living area. Hire an HVAC contractor to make the required repairs.

The exhaust vent terminates too close to the ground. It can be blocked by snow or debris, allowing flue gases to enter the living area. Hire an HVAC contractor to make the required repairs.

The exhaust vent terminates too close to a window. This can allow flue gases to enter the living area. Hire an HVAC contractor to make the required repairs.

The exhaust vent is improperly terminated. It is too close to the soffit and does not adhere to the 3-2-10 rule. This is a back-drafting and fire hazard. Hire an HVAC contractor to make the required repairs.

The exhaust pipe has been recalled due to safety concerns. Hire an HVAC contractor to replace the pipe immediately.

Draft Hood “Spill Switch”: Spill switches on furnace and boiler draft hood shut down the appliance if back-drafting occurs. They detect heat and/or combustion gases. When these fall back on to the switch the assumption is improper drafting.

The exhaust pipe has acidic precipitate. This implies a drafting problem that can permit flue gases to enter the living area. Hire an HVAC contractor to evaluate the system and to make required repairs.

The draft inducer fan is damaged or inoperative. This is a safety hazard that affect proper operation and can permit flue gases to enter the dwelling. Hire an HVAC contractor to make the required repairs.

The barometric damper is inoperative. This is a safety concern that affects the proper exhausting of combustion gases through the flue. Hire an HVAC contractor to make the required repairs.

The barometric damper is missing. This is a safety concern that affects the proper exhausting of combustion gases through the flue. Hire an HVAC contractor to make the required repairs.