(a) Scope.

(1) These standards of practice apply when a professional inspector or real estate inspector who is licensed under this chapter accepts employment to perform a real estate inspection for a prospective buyer or seller of real property.

(2) These standards of practice define the minimum requirements for a real estate inspection conducted on a one to four family unit that is substantially completed. Substantially completed means the stage of construction when a new building, addition, improvement, or alteration to an existing building can be occupied or used for its intended purpose.

(3) For the purposes of these standards of practice a real estate inspection:

(A) is a limited visual survey and basic performance evaluation of the systems and components of a building using normal controls that provides information regarding the general condition of a residence at the time of inspection.

(B) is not intended to be a comprehensive investigation or exploratory probe to determine the cause or effect of deficiencies noted by the inspector; and

(C) does not require the use of:

(i) specialized equipment, including but not limited to:

(I) thermal imaging equipment;

(II) moisture meters;

(III) gas or carbon monoxide detection equipment;

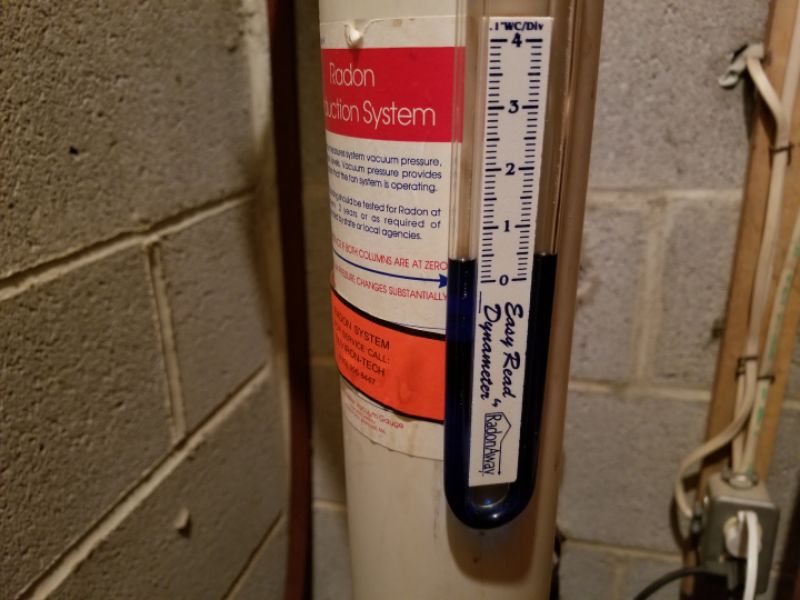

(IV) environmental testing equipment and devices;

(V) elevation determination devices; or

(VI) ladders capable of reaching surfaces over one story above ground surfaces; or

(ii) specialized procedures, including but not limited to:

(I) environmental testing;

(II) elevation measurement;

(III) calculations; or

(IV) any method employing destructive testing that damages otherwise sound materials or finishes.

(4) These standards of practice do not prohibit an inspector from providing a higher level of inspection performance than required by these standards of practice or from inspecting components and systems in addition to those listed under the standards of practice.

(b) Definitions.

(1) Accessible–In the reasonable judgment of the inspector, capable of being approached, entered, or viewed without:

(A) hazard to the inspector;

(B) having to climb over obstacles, moving furnishings or large, heavy, or fragile objects;

(C) using specialized equipment or procedures;

(D) disassembling items other than covers or panels intended to be removed for inspection;

(E) damaging property, permanent construction or building finish; or

(F) using a ladder for portions of the inspection other than the roof or attic space.

(2) Chapter 1102–Texas Occupations Code, Chapter 1102.

(3) Component–A part of a system.

(4) Cosmetic–Related only to appearance or aesthetics, and not related to performance, operability, or water penetration.

(5) Deficiency–In the reasonable judgment of the inspector, a condition that:

(A) adversely and materially affects the performance of a system, or component; or

(B) constitutes a hazard to life, limb, or property as specified by these standards of practice.

(6) Deficient–Reported as having one or more deficiencies.

(7) Inspect–To operate in normal ranges using ordinary controls at typical settings, look at and examine accessible systems or components and report observed deficiencies as specified by these standards of practice.

(8) Performance–Achievement of an operation, function or configuration relative to accepted industry standard practices with consideration of age and normal wear and tear from ordinary use.

(9) Report–To provide the inspector’s opinions and findings on the standard inspection report form as required by §535.222 and §535.223 of this title.

(10) Standards of practice–§§535.227 – 535.233 of this title.

(c) General Requirements.

The inspector shall:

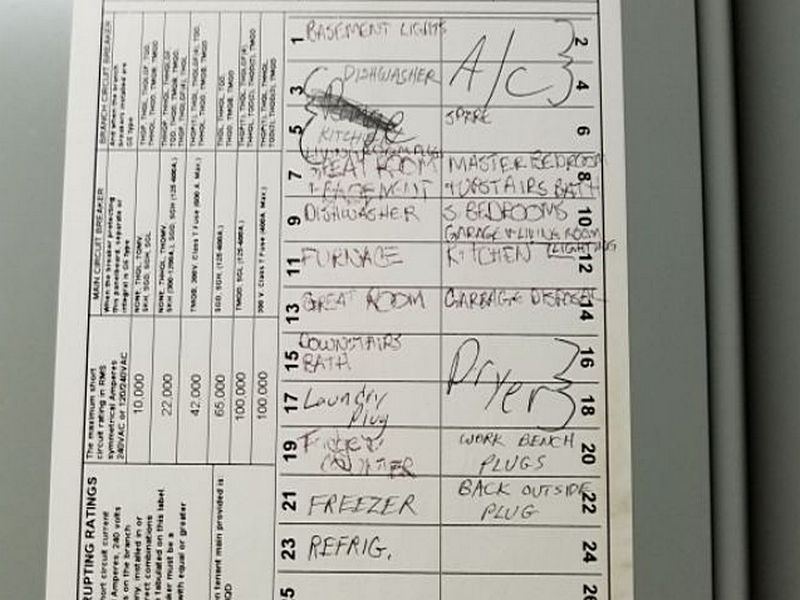

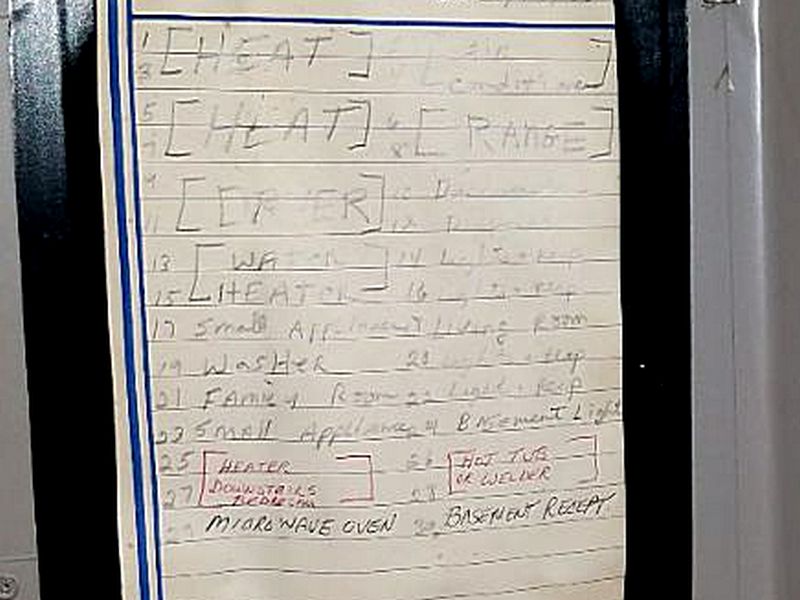

(1) operate fixed or installed equipment and appliances listed herein in at least one mode with ordinary controls at typical settings;

(2) visually inspect accessible systems or components from near proximity to the systems and components, and from the interior of the attic and crawl spaces; and

(3) complete the standard inspection report form as required by §535.222 and §535.223 of this title.

(d) General limitations.

The inspector is not required to:

(1) inspect:

(A) items other than those listed within these standards of practice;

(B) elevators;

(C) detached buildings, decks, docks, fences, waterfront structures, or related equipment;

(D) anything buried, hidden, latent, or concealed;

(E) sub-surface drainage systems;

(F) automated or programmable control systems, automatic shut-off, photoelectric sensors, timers, clocks, metering devices, signal lights, lightning arrestor system, remote controls, security or data distribution systems, solar panels or smart home automation components; or

(G) concrete flatwork such as driveways, sidewalks, walkways, paving stones or patios;

(2) report:

(A) past repairs that appear to be effective and workmanlike except as specifically required by these standards;

(B) cosmetic or aesthetic conditions; or

(C) wear and tear from ordinary use;

(3) determine:

(A) the presence or absence of pests, termites, or other wood-destroying insects or organisms;

(B) the presence, absence, or risk of:

(i) asbestos;

(ii) lead-based paint;

(iii) mold, mildew;

(iv) corrosive or contaminated drywall “Chinese Drywall”; or

(v) any other environmental hazard, environmental pathogen, carcinogen, toxin, mycotoxin, pollutant, fungal presence or activity, or poison;

(C) types of wood or preservative treatment and fastener compatibility; or

(D) the cause or source of a condition;

(E) the cause or effect of deficiencies;

(F) any of the following issues concerning a system or component:

(i) insurability or warrantability;

(ii) suitability, adequacy, compatibility, capacity, reliability, marketability, or operating costs;

(iii) recalls, counterfeit products, or product lawsuits;

(iv) life expectancy or age;

(v) energy efficiency, vapor barriers, or thermostatic performance;

(vi) compliance with any code, listing, testing or protocol authority;

(vii) utility sources; or

(viii) manufacturer or regulatory requirements, except as specifically required by these standards;

(4) anticipate future events or conditions, including but not limited to:

(A) decay, deterioration, or damage that may occur after the inspection;

(B) deficiencies from abuse, misuse or lack of use;

(C) changes in performance of any component or system due to changes in use or occupancy;

(D) the consequences of the inspection or its effects on current or future buyers and sellers;

(E) common household accidents, personal injury, or death;

(F) the presence of water penetrations; or

(G) future performance of any item;

(5) operate shut-off, safety, stop, pressure or pressure-regulating valves or items requiring the use of codes, keys, combinations, or similar devices;

(6) designate conditions as safe;

(7) recommend or provide engineering, architectural, appraisal, mitigation, physical surveying, realty, or other specialist services;

(8) review historical records, installation instructions, repair plans, cost estimates, disclosure documents, or other reports;

(9) verify sizing, efficiency, or adequacy of the ground surface drainage system;

(10) verify sizing, efficiency, or adequacy of the gutter and downspout system;

(11) operate recirculation or sump pumps;

(12) remedy conditions preventing inspection of any item;

(13) apply open flame or light a pilot to operate any appliance;

(14) turn on decommissioned equipment, systems or utility services; or

(15) provide repair cost estimates, recommendations, or re-inspection services.

(e) In the event of a conflict between the general provisions set out in this section, and the specific provisions specified elsewhere in the standards of practice, specific provisions shall take precedence.

(f) Departure provision.

(1) An inspector may depart from the inspection of a component or system required by the standards of practice only if:

(A) the inspector and client agree the item is not to be inspected;

(B) the inspector is not qualified to inspect the item;

(C) in the reasonable judgment of the inspector, the inspector determines that:

(i) conditions exist that prevent inspection of an item;

(ii) conditions or materials are hazardous to the health or safety of the inspector; or

(iii) the actions of the inspector may cause damage to the property; or

(D) the item is a common element of a multi-family development and is not in physical contact with the unit being inspected, such as the foundation under another building or a part of the foundation under another unit in the same building;

(2) If an inspector departs from the inspection of a component or system required by the standards of practice, the inspector shall:

(A) notify the client at the earliest practical opportunity that the component or system will not be inspected; and

(B) make an appropriate notation on the inspection report form, stating the reason the component or system was not inspected.

(3) If the inspector routinely departs from inspection of a component or system required by the standards of practice, and the inspector has reason to believe that the property being inspected includes that component or system, the earliest practical opportunity for the notice required by this subsection is the first contact the inspector makes with the prospective client.

(g) Enforcement. Failure to comply with the standards of practice is grounds for disciplinary action as prescribed by Chapter 1102.